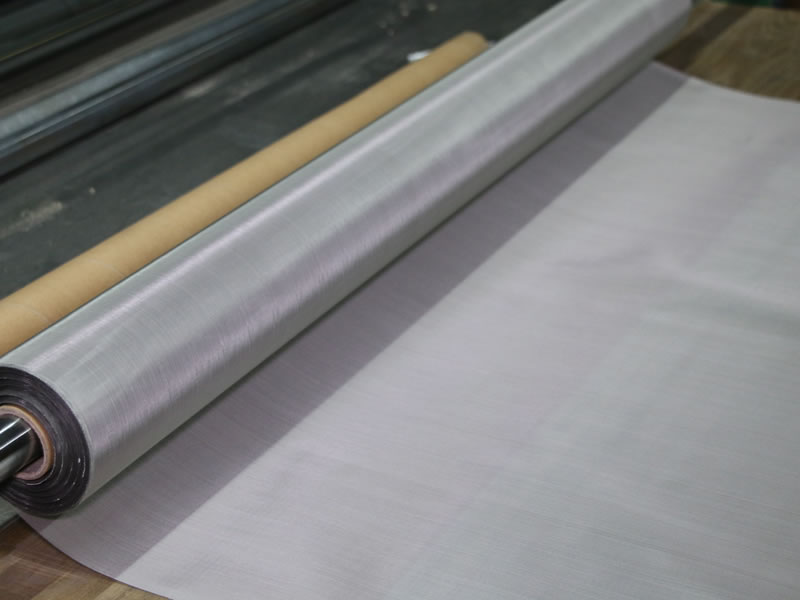

Product Name: Stainless Steel Wire Mesh

Stainless steel wire mesh, with its excellent resistance against acid, alkali, heat and corrosion, find extensive uses in processing of oils, chemicals, food, pharmaceuticals, also sorting and screening of solid, liquid and gas in mine, metallurgy, etc.

Brand Name:

Hebei Top Imp& Exp Co., Ltd

Place of Origin:

Room 2916, Block B, Mixc. No.108 Zhongshan West Road, Qiaoxi Zone, Shijiazhuang, Hebei

Payment Options Available

a. T/T

b. L/C

c. D/P

d. OA

Material: ss304, ss304l, ss316, ss316l, ss310 etc.

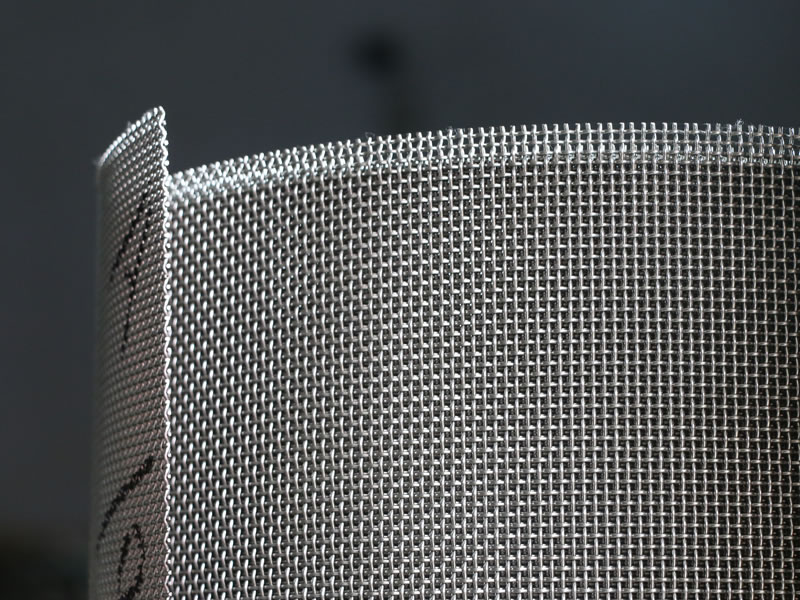

Weaving patterns involved: plain weave, twill weave and dutch weave.

Property: Acid resisting, alkali resisting, heat resisting, durable

Application: Sifting and filtering in acid and alkali conditions. Slurry net in petroleum, sifting and screening mesh in chemical and chemical fiber industry, acid washing mesh in electric plating industry.

Roll Width: 36", 40", 48", 60"

Roll Length: 25Ft, 50Ft and 100Ft

Stainless Steel Wire Mesh Standard Grade made from plain weave or twill weave, materials are available in ANSI304 ANSI316 also other stainless steel 300 series and 400 series.

Type 304

Often referred to as "18-8" ( 18% chromium, 8% nickel ) T-304 is the basic stainless alloy mostly commonly utilized for wire cloth weaving. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 1400 Degrees Fahrenheit.

Type304L

Type 304 L is very similar to T-304, the difference being the reduced carbon content for better weaving and secondary welding characteristics.

Type 316

Stabilized by the addition of 2% molybdenum, T-316 is an "18-8" alloy.Type 316 has better resistance to pitting corrosion than the other chromium-nickel stainless steels where brines, sulphur-bearing water or halogen salts, such as chlorides are present. A valuable property of T-316 is high creep strength at elevated temperatures. Other mechanical properties and fabricating characteristics are similar to T-304.

Wire cloth woven of T-316 has extensive use in chemical processing when better corrosion resistance is required than the regular chromium-nickel types.

Type 316 L

Type 316 L is very similar to T-316, the difference being the reduced carbon content for better wire cloth weaving and secondary welding characteristics.

Uses: Stainless steel wire mesh and stainless steel wire cloth products are widely used in petroleum, chemical industry, environment protection, mine, airspace, paper-making, electronic, metallurgy etc. Special size and specification are available according to customers requirement.

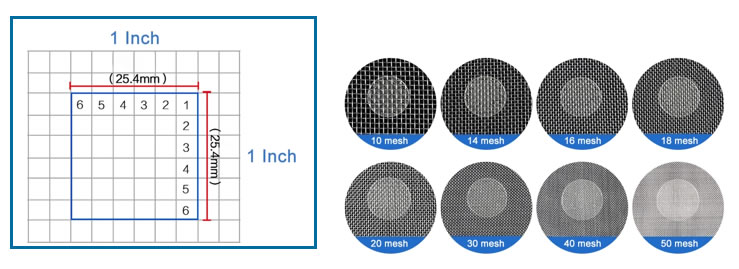

Specification of Plain Woven

| mesh/inch | wire diameter mm | aperture mm | - | mesh/inch | wire diameter mm | aperture mm |

| 2 | 1.80 | 10.90 | 60 | 0.15 | 0.273 | |

| 3 | 1.60 | 6.866 | 70 | 0.14 | 0.223 | |

| 4 | 1.20 | 5.15 | 80 | 0.12 | 0.198 | |

| 5 | 0.91 | 4.17 | 90 | 0.11 | 0.172 | |

| 6 | 0.80 | 3.433 | 100 | 0.10 | 0.154 | |

| 8 | 0.60 | 2.575 | 120 | 0.08 | 0.132 | |

| 10 | 0.55 | 1.990 | 140 | 0.07 | 0.111 | |

| 12 | 0.50 | 1.616 | 150 | 0.065 | 0.104 | |

| 14 | 0.45 | 1.362 | 160 | 0.065 | 0.094 | |

| 16 | 0.40 | 1.188 | 180 | 0.053 | 0.088 | |

| 18 | 0.35 | 1.060 | 200 | 0.053 | 0.074 | |

| 20 | 0.30 | 0.970 | 250 | 0.04 | 0.061 | |

| 26 | 0.28 | 0.696 | 300 | 0.035 | 0.049 | |

| 30 | 0.25 | 0.596 | 325 | 0.03 | 0.048 | |

| 40 | 0.21 | 0.425 | 350 | 0.03 | 0.042 | |

| 50 | 0.19 | 0.318 | 500 | 0.025 | 0.0385 |

Specification of Twill Weave

| mesh/inch | wire diameter mm | aperture mm | mesh/inch | wire diameter mm | aperture mm | |

| 100 | 0.14 | 0.114 | 325 | 0.035 | 0.0443 | |

| 120 | 0.1 | 0.111 | 350 | 0.032 | 0.0405 | |

| 150 | 0.09 | 0.079 | 400 | 0.03 | 0.0335 | |

| 180 | 0.07 | 0.071 | 450 | 0.026 | 0.0304 | |

| 200 | 0.06 | 0.067 | 500 | 0.025 | 0.0258 | |

| 250 | 0.045 | 0.0566 | 600 | 0.018 | 0.0243 | |

| 300 | 0.04 | 0.0446 | 635 | 0.018 | 0.022 |

Specification of Plain Dutch Weave

| mesh/inch | Absolute micron retention (µm) | Weight (Kg/m2) | Cloth Thickness (mm) |

| 80*300 | 32-36 | 0.98 | 0.25 |

| 80*400 | 32-45 | 0.82 | 0.23 |

| 50*250 | 56-63 | 1 | 0.32 |

| 50*280 | 71-75 | 1 | 0.32 |

| 40*200 | 75-80 | 1.3 | 0.4 |

| 30*150 | 80-100 | 1 | 0.5 |

| 24*110 | 100-112 | 2.5 | 0.76 |

| 22*140 | 140-170 | 2.1 | 0.66 |

| 20*150 | 160-180 | 1.55 | 0.5 |

| 20*150 | 170-190 | 1.6 | 0.55 |

| 18*100 | 200-210 | 2.05 | 0.69 |

| 14*110 | 220-240 | 2.15 | 0.72 |

| 12*95 | 240-260 | 2.3 | 0.79 |

| 14*88 | 280-300 | 3.15 | 0.76 |

| 10*90 | 270-290 | 2.5 | 0.93 |

| 12*64 | 280-300 | 4.1 | 1.21 |